Electric Wire Junction Metal Box Production Line Punching Machine

Basic Info.

| Model NO. | BLC |

| Punch Shape | Open Punch |

| Slider Movement | Double Action |

| Slider Drive Mechanism | Crank Press |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Power Source | Pneumatic |

| Precision | High Precision |

| Certification | CE |

| Condition | New |

| Producte | Junction Box |

| Shape Design | by Hard Chrome Olated/Nitrogen |

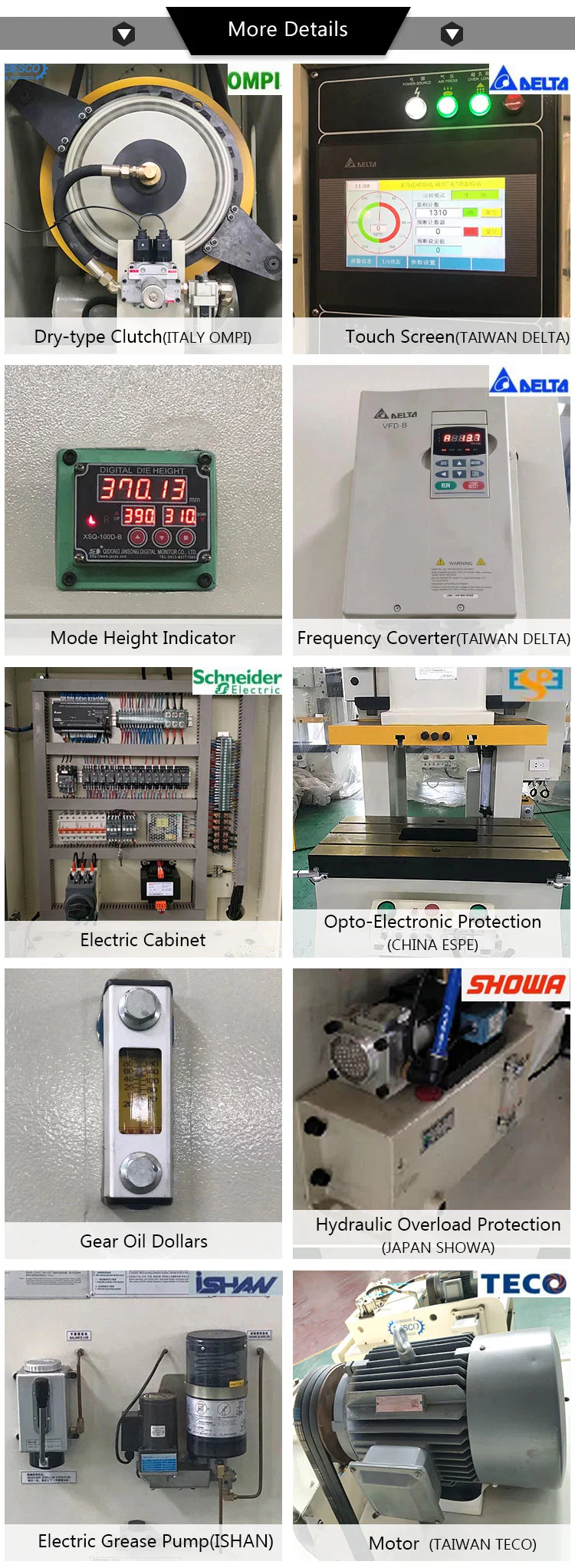

| Parts | International Brand Accessories |

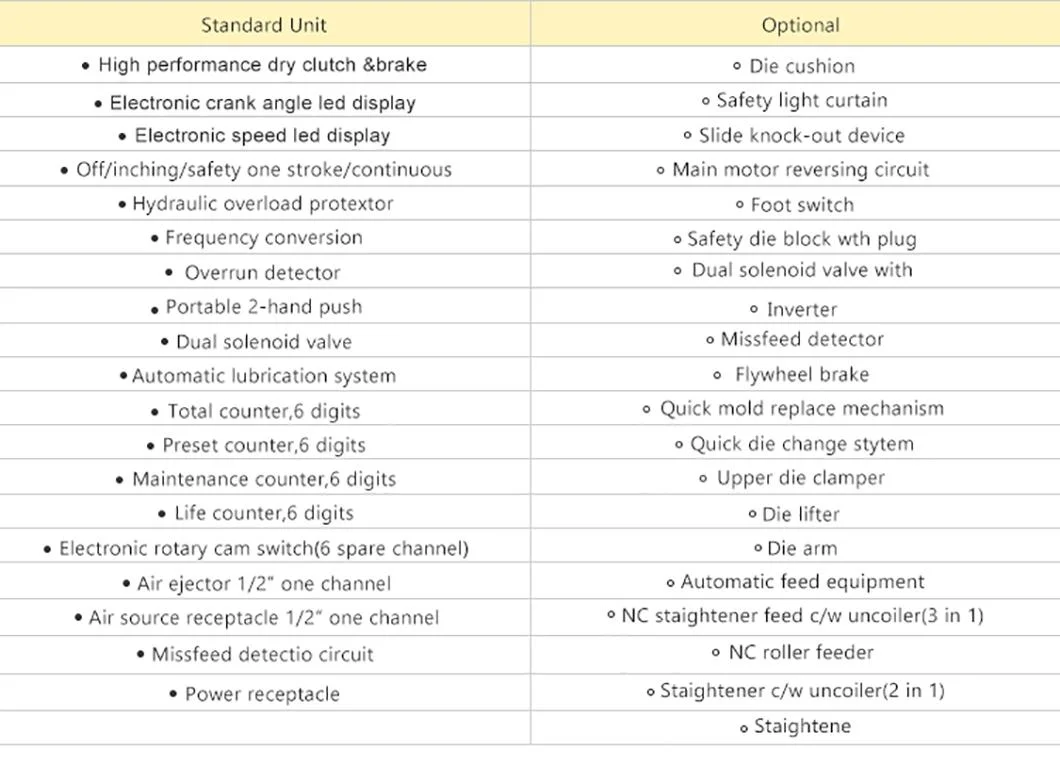

| Standard Unit 1 | Frequency Conversion |

| Standard Unit 2 | High Performance |

| Use | Takeout for Bakery |

| Using Industry | Catering Sector |

| Stationarity | The Starting Balancer Device Is Adopted |

| Texture | High Quality Steel Plate for Fuselage |

| Security | Adopt Safety Double Solenoid Valve and Hydraulic O |

| Model | Fully Automatic Production Line |

| Function | High Efficiency Production |

| Accuracy | +-0.01mm |

| Advantage | High Precision |

| Transport Package | Nude Packing |

| Specification | 1745*2000*3059 |

| Trademark | BESCOMT |

| Origin | Shandong |

| HS Code | 8428399000 |

| Production Capacity | 1000+ |

Product Description

Product Description

Electric wire junction metal box production line punching machine

1.The machine body is welded of quality steel sheet and treated by tension elimination, improve stability and reliability of precision of the machine. 2.In order to guarantee the machine running in stable and smooth,adopts the design of symmetrical two slid boards with balancer.3.The precision of mold adjusting up to 0.1mm,safety,reliable and convenient.4.Crank,gear,connectbar are oxidized hardening and milled, having super comprehensive mechanical performance and durable function. 5.Reasonable structural design, is convenient for automatic production and line production.6.Used reliable high intensity clutch/brake and twin electromagnetic vale, overloading protector can guarantee safe production all-around.7.Used high-grade alloy steel, double crank, wide work center with connection bar structure, the optimized design is suitable for large sizes and the mold bearing large impact loading as well as pressing of eccentric mold.8.Adopted closed electric loop circuit, have compatible with any automatic equipments.Keywords: Junction box production line,Junction box making machine,BLC punching machine,Double Crank open type High precision pneumatic press machine

Detailed Photos

| Double Crank Open Type High Precision Pneumatic Press Machine--BLC | ||||||

| Specification | BLC100 | BLC160 | BLA200 | BLC250 | BLC315 | |

| Model | V/H | V/H | V/H | V/H | V/H | |

| Capacity | Ton | 110 | 160 | 200 | 250 | 315 |

| Rate tonnage point | mm | 5/3 | 6/3 | 6/3 | 7/3.5 | 7/3.5 |

| Stable speed | s.p.m | 35-65/50-100 | 30-55/40-85 | 25-45/35-70 | 20-35/30-60 | 20-35/30-50 |

| Stroke | mm | 180/110 | 200/130 | 250/150 | 280/170 | 300/170 |

| Die height | mm | 400/435 | 450/485 | 500/550 | 550/605 | 550/615 |

| Slider adjustment | mm | 100 | 100 | 120 | 120 | 120 |

| Slider area | mm | 1400*500*70 | 1600*550*70 | 1850*650*95 | 2100*700*95 | 2100*700*95 |

| Bolster area | mm | 1800*650*130 | 2000*760*150 | 2400*840*170 | 2700*900*170 | 2750*900*190 |

| Main motor | kw.p | 11*4 | 15*4 | 18.5*4 | 22*4 | 30*4 |

| Air pressure | kg/cm² | 6 | ||||

| Presses precison | GB/JIS 1class | |||||

| Presses dimension | mm | 1745*2000*3059 | 1940*2200*3709 | 2235*2620*3849 | 2545*3000*4303 | 2545*3010*4689 |

| Die cushion capacity | Ton | 14.2 | 20 | 27.5 | 45.5 | 48 |

| Die cushion work part dimension | mm² | 350*235*2groups | 410*260*2groups | 540*350*2groups | 640*470*2groups | 640*470*2groups |

Company Introduction

3.Our factory can send our engineer to the customer's factory install, commission and training freelyThe customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to

our factory to learn the operation and maintains freely.

Transport And Pack

We are currently reviewing our product packaging from the angles of waste-reduction and resource-saving. We are also working on improving transportation efficiency from the design phase of product development.

1.Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2.All the spare parts of the machine were covered by the some soft materials mainly using pearl wool.

3.The outmost is wooden case with fixed formwork.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

FAQ

1.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

2.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance before delivery 3.Guaranty covers?

Main parts of the machine , wearing parts not included .PARTS DELIVERY. Within 5 days by DHL / Fexed . 4.About our after-sale service:

Customer service 24 hours online, you can send technicians to your country to repair the machine. Buyer shall bear all costs including visa, round trip airfare and suitable accommodation and buyer shall pay usd 100 / day salary.

5.How to replace machine parts?

Parts adopt international brands, good quality, no need to replace within 3-5 years, convenient to buy suitable parts locally.

6.Installation&Commissioning:

Usually solved by video conference, if necessary, can be dispatched to the door installation debugging and maintenance of technical personnel.