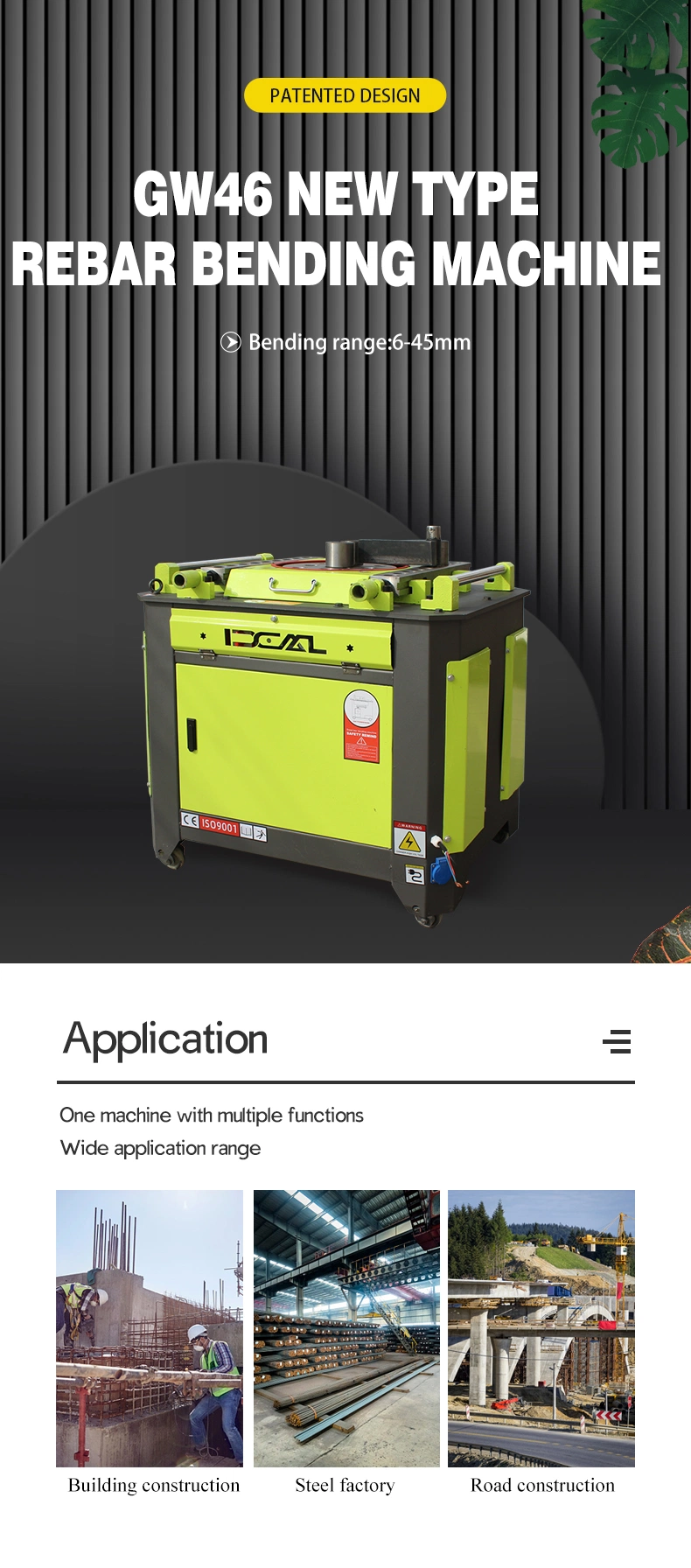

Gw46 Steel Bar Bending Rod Machine 42mm Stirrup Automatic Rebar Bender Machine

Basic Info.

| Model NO. | GW46 |

| Condition | New |

| Certification | ISO 9001:2000, ISO 9001:2008, CE |

| Automation | Semi-Automatic |

| Suitable for | Carbon Steel, Stainless Steel |

| Type | Cnc Bending Machine |

| Bending Speed | 28 Time/Min |

| Motor Power | 3kw |

| Bending Range | 6-42mm |

| Input Voltage | 220V/380VAC ,415VAC or Customized |

| Weight | 310kg |

| Usage | Stirrup Making or Hoop Making |

| Disc Diameter | 350mm |

| Name | Steel Bar Bending Machine |

| Color | Yellow or Customized |

| Transport Package | Iron Frame and Cartion |

| Specification | 850*900*900mm |

| Trademark | IDEAL |

| Origin | Henan |

| HS Code | 8461500090 |

| Production Capacity | 5000 Set/Month |

Packaging & Delivery

Package Size 94.00cm * 89.00cm * 90.00cm Package Gross Weight 400.000kgProduct Description

Gw46 Steel Bar Bending Machine 6-42mm Stirrup Automatic Rebar Bender MachineTable parameter

It is mainly used in construction sites for bending A3 round bar, III class reinforced bar, flat bar, and square bar.It can bend the rebar to kinds of Geometric shapes for construction sites.

| Model | GW46 |

| Round Bar | Φ6-Φ42mm |

| III-CLASS Bar | Φ6-Φ36mm |

| Power | 3KW |

| Input Voltage | 3PHASE:220/380/415VAC |

| Overall Size | 940*890*900mm |

| Weight | 400KG |

In 2000, "Ideal machinery" started a small workshop in Changge city, assembling rebar cutting machines and bending machines. through 20 years of development and relying on word-of-mouth advertising, our product involved kinds of the light construction machine. In order to push our machines into the overseas market, the Brand "Ideal machinery" is established in 2015 and started export trading. until now, nearly 10,000 sets of our machines are servicing the overseas construction sites now.

Q1. What can we do if there are problems with the products?

A: Our engineers will analyze the problem for you and find the best solution. If problems happened within the guaranteed time, we can replace the components for you free of charge. We have dealers in some countries, for some technical problems which you can not solve by yourself.

Q2. What is the delivery time for your products?

A: Once we promise the delivery time, we will try our best to fulfill it. Special procedures such as emergency inventory will be used to maintain your uninterrupted supply of the products.

Q3. Is there any guarantee for your products?

A: Most of our products have one year guarantee(for the main parts).

Q4. How can you control your product quality?

A: Quality is always considered the most important part of our manufacturing process. All of our products come under a strict quality control system from raw material inspection, component inspecting,semi-finished product inspecting, performance test of finished products, to random inspection before delivery.